It was an early start at the SMC Huntsville Workshop. Our goal today was to build a 45 motor in a day, or get as far as we could. The cases had been fitted with new Torrington bearings by SMC VP Roy Chapman at the SMC machine shop in Adairsville, GA. Roy had set the cases up with the Torrington conversion and had bolted the cases together with a dry end play of .011. In attendance was SMC President Mike McCloud, Erik Bahl, Dorsey Upatain, Jon Lindberg and Cecil Frost.

The Torrington bearing

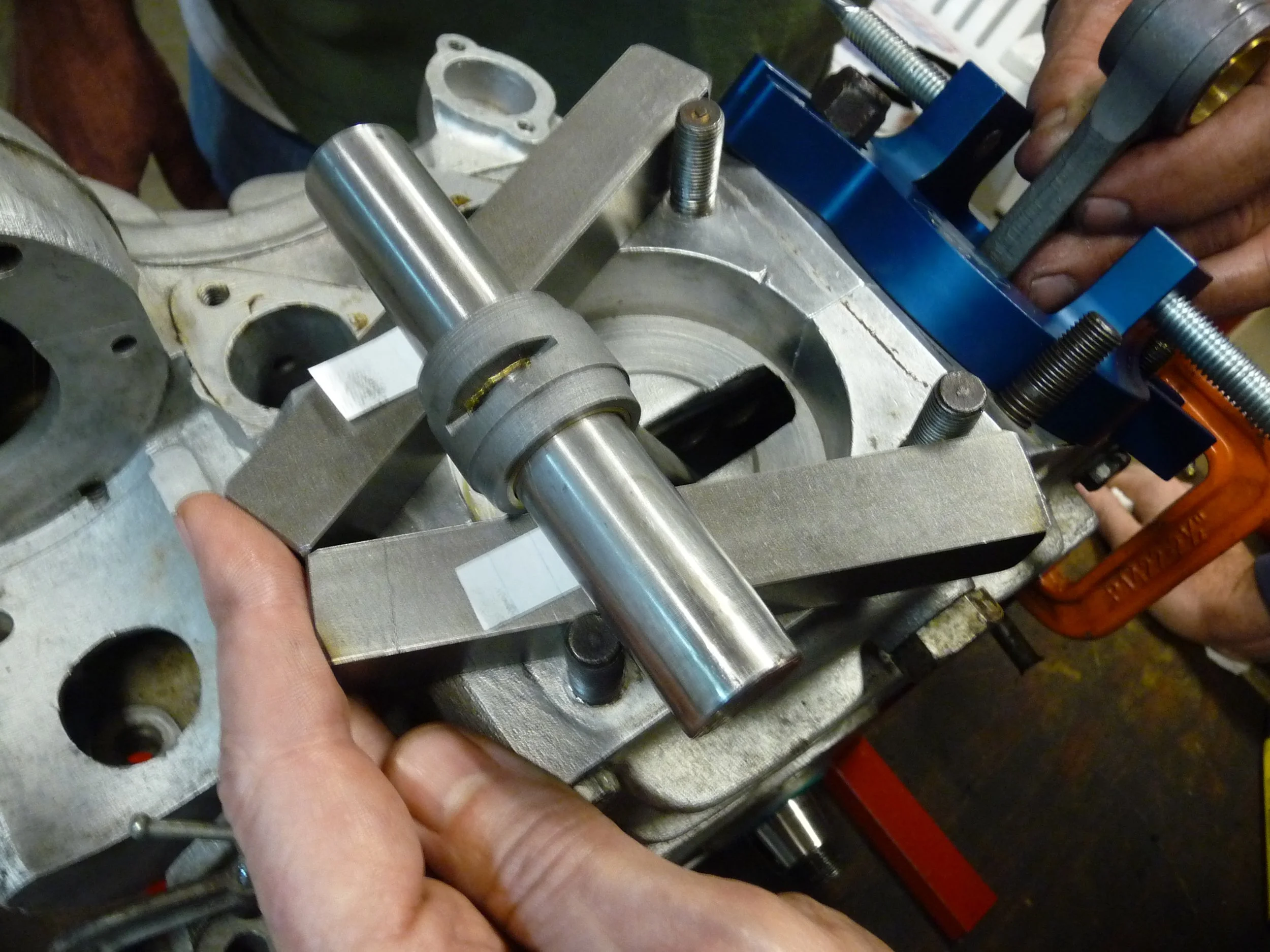

Dorsey, Cecil and Erik doing a wet test fit.

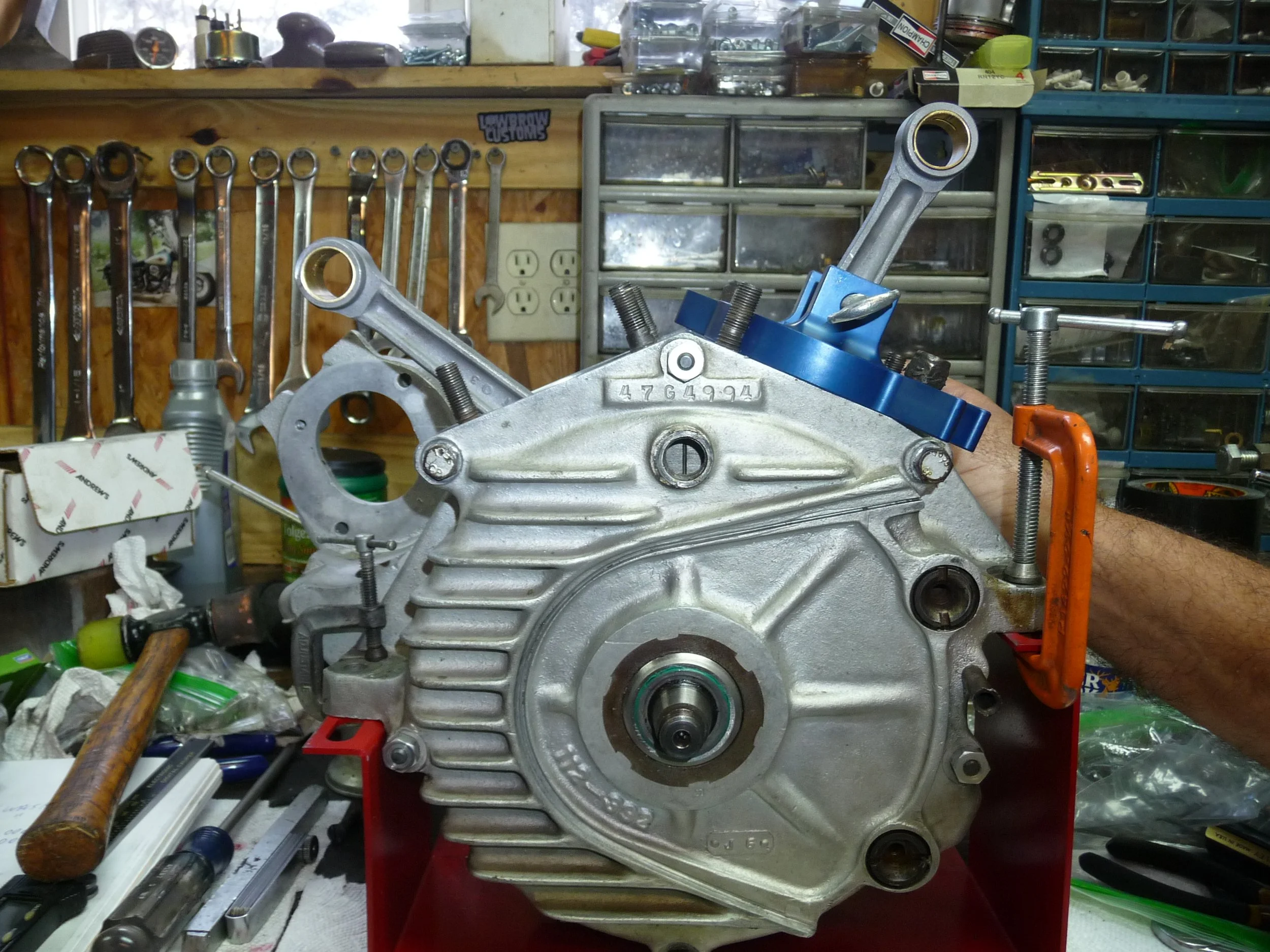

After doing a wet fit we decided we wanted a little more end play and decided to take a .001 off each thrust collar. Jon Lindberg suggested the method to remove the material and it was a outstanding success.

Checking the end play one last time

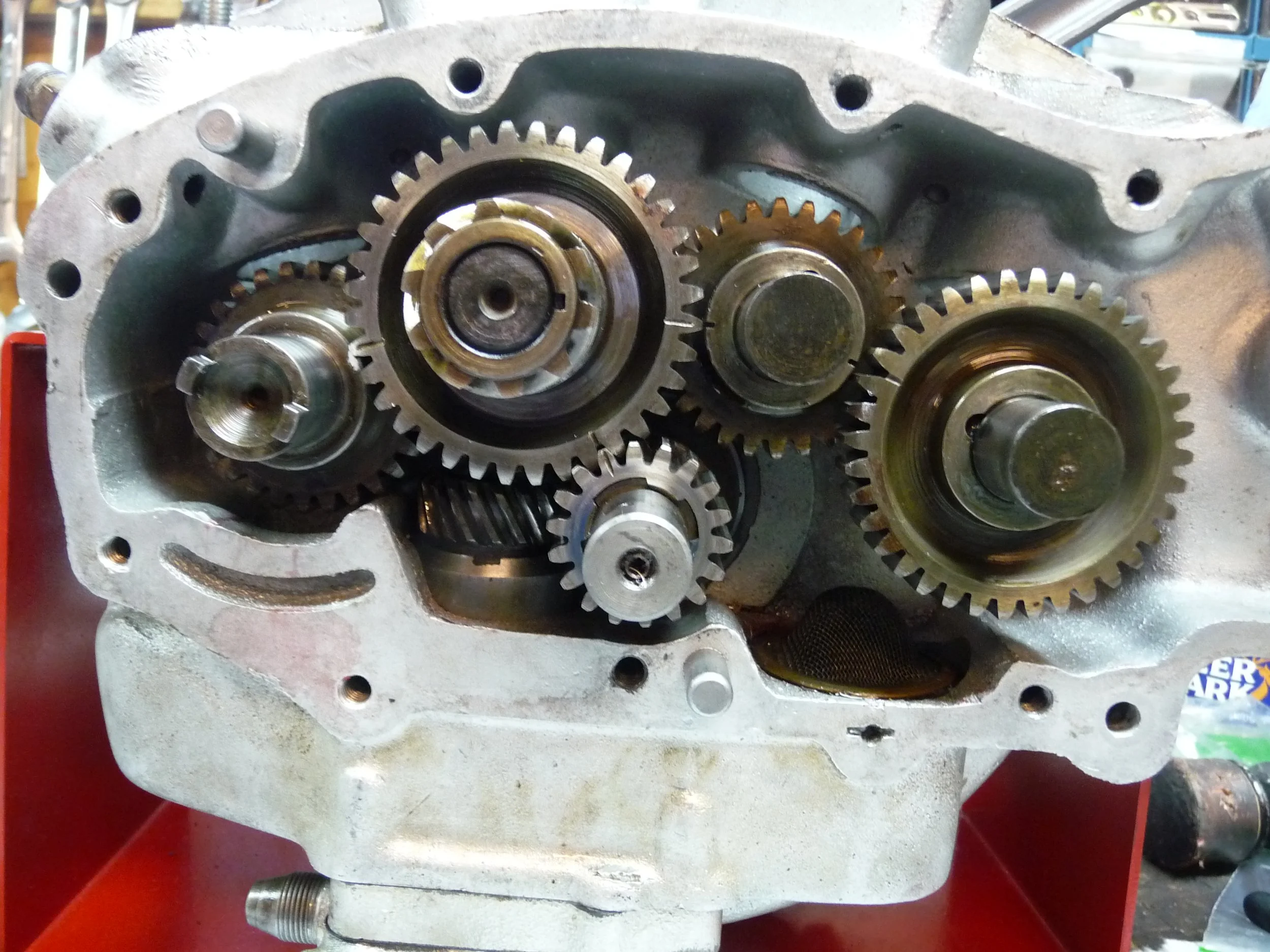

Lightly sealed the cases and on to cam chest

Erik was the cam shim mathematician

Cam cover went on and off at least 5 times. I lost count to be honest

Dorsey having a little fun rebuilding the oil pump

Starting to go together!

Finding the mark!

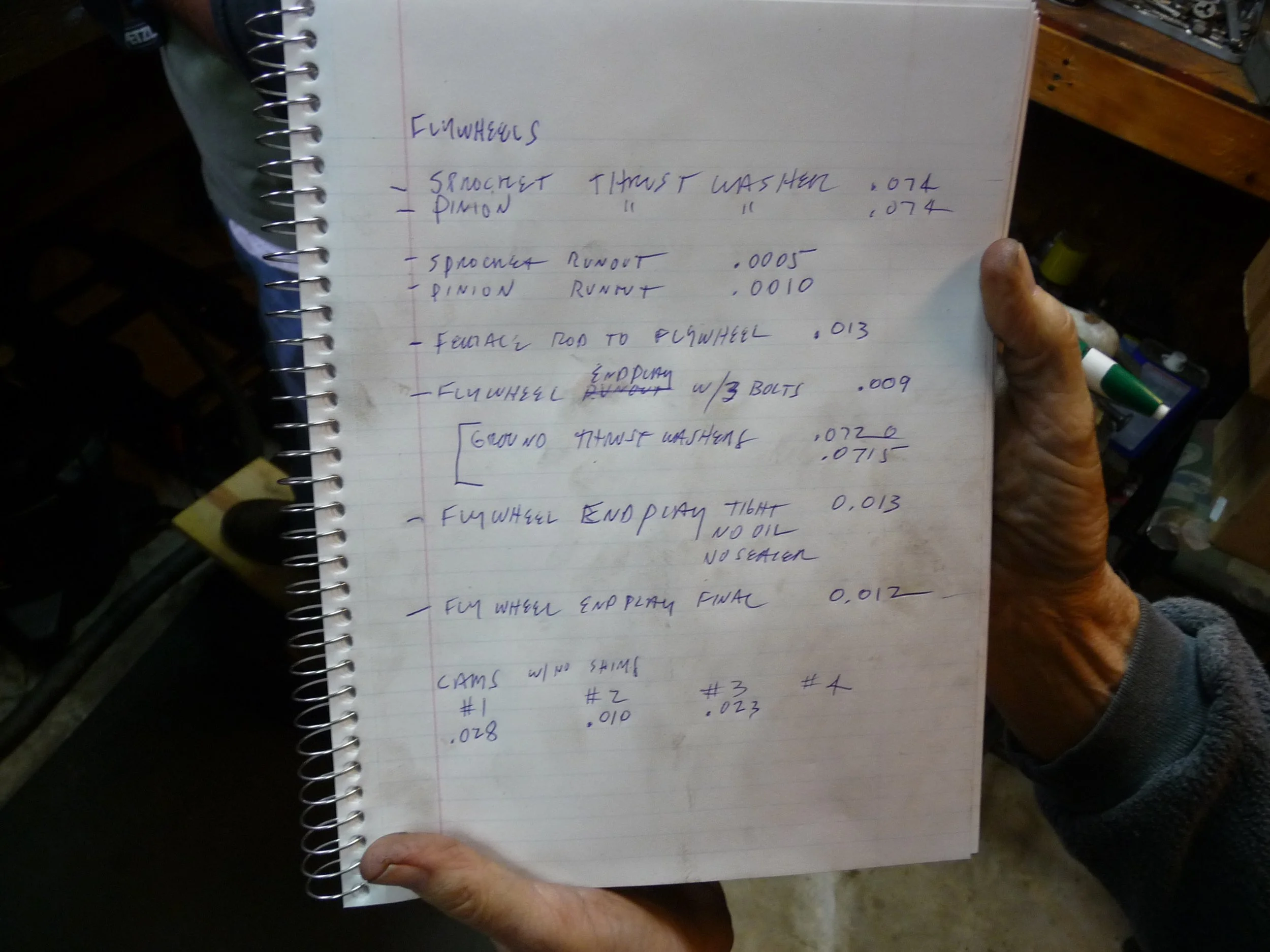

build sheet notes

Lining up the marks

Preparing for rod alignment

Preforming rod alignment

It was a great day of fun and learning. Everyone’s experience came together for a nice job! There are a few items/parts to be completed. Those items include new springs for oil pump and the seal ring inside cam cover for generator gear. All parts needed for these repairs have been ordered and are in route. The top end is currently in the hands of Roy and should be ready soon. Next up will be the transmission where some decisions are yet to be made. Stock versus 4 speed gear set.