Since the tech day in November there has been a lot of forward progress on the 47 Knucklehead. I know everyone was busy for the holidays and I tackled this work solo but thought it would be good to update the Smoky Mountain Team as everyone has had their paws on this machine.

Once I removed the damaged intake nipple some of you might recall I brought the head and two possible replacement nipples (one standard and one oversize) to the SMC Christmas party to solicit advice on how to move forward. I ended up using the standard size nipple and coated both the threads and securing rivet in Lab-Metal High-Temp. This is a brush on compound that is good to 1000F. This was at the recommendation of Roy Chapman and should result in an air leak free intake nipple. Photo below shows the new intake nipple in place.

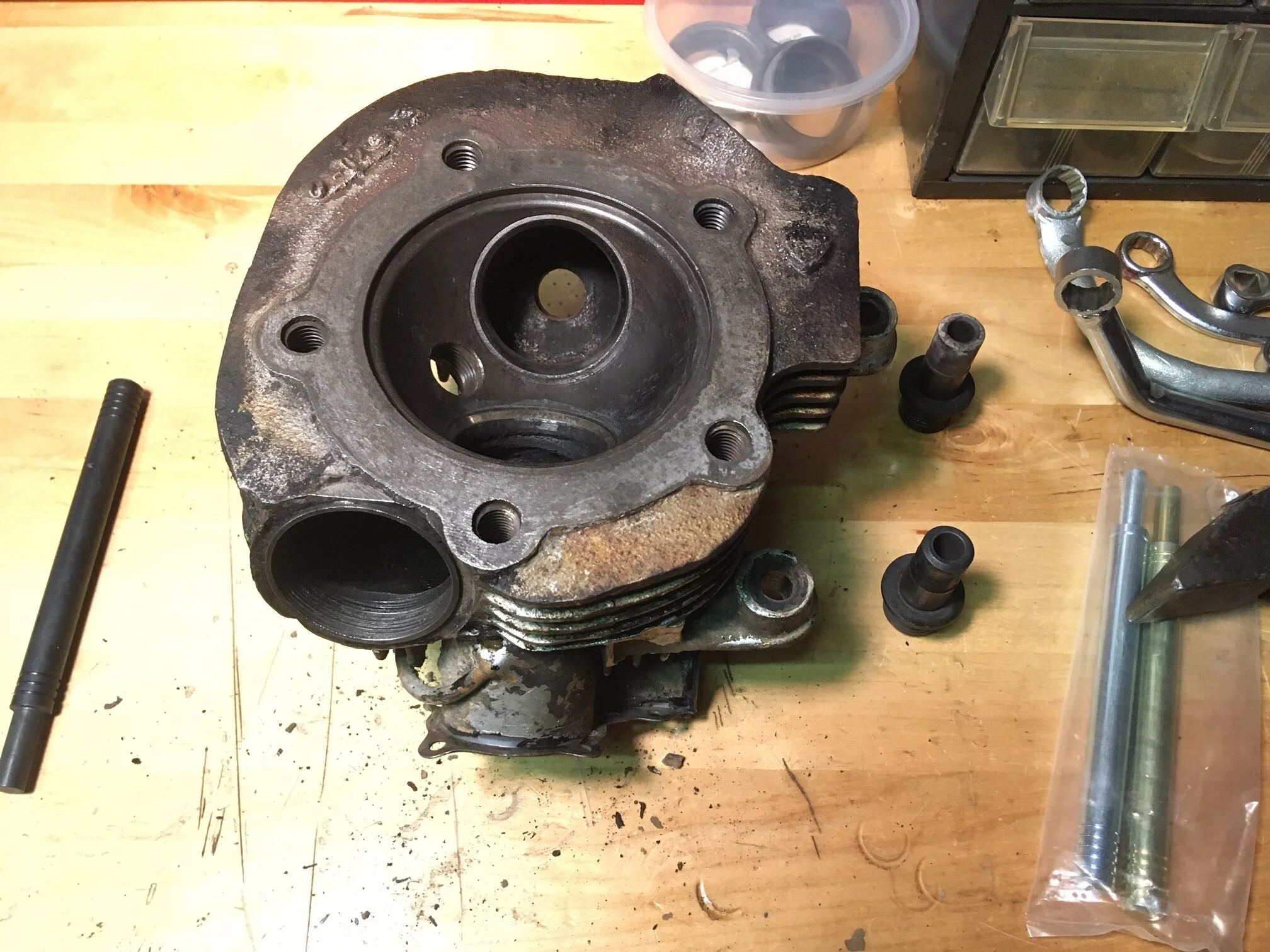

I also decided to replace the valves, guides and springs in both heads. Below you can see where I knocked both valve guides out of the head (they are on the right). Turns out all of my guides were +0.002” over. After doing measurements I replaced them with the same size. You will also notice the intake nipple has been removed.

Once the guides were installed, they need to be reamed out to ensure proper guide to valve stem clearance. The manual calls for 0.004” to 0.006”. I took care of that with the hand reamer below.

Once the valve guides were finished, I recut the valve seats to clean them up for the new valves. Below shows the new valves in place.

Here is a top view showing the new springs.

Of course, with both heads done, I started to get excited as I thought I was going to reinstall the refreshed heads, do a couple other minor repairs and get this old girl back on the road in short order! Well nothing is ever as easy as you hope. Remember, all this work was being done with the motor still mounted in the frame. One of those minor jobs was to make sure the motor was mounted properly as I lost the top mount during the Cross Country Chase. So, I was examining the lower front motor mounts, and something looked a little off in the frame motor mount. I started to scrape off some of that 70-year-old dirt and grease and lo and behold the frame forging was cracked. Well, out comes the motor and I cleaned everything up to get a better look. OUCH. Notice the nice crack in the photo below. The next task is to weld this up and start to move this project forward again. It’s just another slight delay….